Provide OEM services and solutions

We specialize in manufacturing custom USB cables and power adapters.

Reliability

Quality

Value

Our Service

OEM &

ODM

We can provide high-quality connectors and power adapters designed for challenging applications.

Design &

Engineering

WJW is a trusted and flexible design collaboration partner that helps clients transform innovative designs into successful products.

Custom Made Products

Our sales and technical staff are adaptable and agile, enabling us to help clients anticipate and prepare for unexpected changes.

Supply Chain Improvement

To support our customers’ supply chain operations, we accept orders in varying quantities and are committed to on-time delivery.

Become our partner

Do you want to have such a supplier?

We are a trusted and flexible design partner that helps clients transform innovative designs into successful products.

Our sales and technical staff are flexible and adaptable, enabling them to help customers anticipate and prepare for unexpected changes.

To meet the needs of our customers’ supply chain operations, we accept orders in different batches and are committed to on-time delivery of products.

We offer professional OEM/ODM customization services for USB data cables and power adapters. With an engineering team that has over ten years of experience, we can provide one-on-one dedicated support to each customer, precisely meeting your specific needs.

We construct strictly according to the unique requirements and specifications of the original manufacturer’s customers, and fully comply with regulations, environmental requirements and safety standards.

Consistent 100% quality is our measure of success. We conduct rigorous inspections on every part before it leaves the factory, and any defects are absolutely unacceptable.

Quality control

![]() We have established a complete production traceability system for every product and built a proprietary quality control system that surpasses industry certifications. This commitment to quality has earned us the high trust of multinational brands and innovative technology clients. As a professional custom manufacturer, we insist on using specialized equipment to rigorously inspect all incoming materials. This meticulous, even somewhat time-consuming, process is the cornerstone of ensuring that every custom cable and adapter reaches the highest quality.

We have established a complete production traceability system for every product and built a proprietary quality control system that surpasses industry certifications. This commitment to quality has earned us the high trust of multinational brands and innovative technology clients. As a professional custom manufacturer, we insist on using specialized equipment to rigorously inspect all incoming materials. This meticulous, even somewhat time-consuming, process is the cornerstone of ensuring that every custom cable and adapter reaches the highest quality.

![]() We strictly adhere to international environmental and safety regulations, including RoHS and REACH, and can meet specific substance control requirements such as PAHs, 6P, NP, and halogen-free (HF) according to customer and product needs. In material selection, we strictly follow the customer’s specified Bill of Materials (BOM). Furthermore, leveraging our mature supply chain resources, we can provide cost optimization or functional upgrade alternatives for USB cables, power adapters, and other related connectors and wires, flexibly responding to your specific needs.

We strictly adhere to international environmental and safety regulations, including RoHS and REACH, and can meet specific substance control requirements such as PAHs, 6P, NP, and halogen-free (HF) according to customer and product needs. In material selection, we strictly follow the customer’s specified Bill of Materials (BOM). Furthermore, leveraging our mature supply chain resources, we can provide cost optimization or functional upgrade alternatives for USB cables, power adapters, and other related connectors and wires, flexibly responding to your specific needs.

![]() Every custom-made cable and power adapter leaving our factory undergoes rigorous quality control and testing processes. Leveraging our global production bases, we reliably deliver hundreds of thousands of products to the international market every month, consistently maintaining high quality and consistency.As a leading expert in customized manufacturing, we continuously keep abreast of the latest technologies and industry certifications, constantly enriching our product knowledge base and process solutions. Through close collaboration between engineers and management, we continuously optimize our manufacturing processes; simultaneously, by providing systematic training to our production team and establishing an efficient environment, we ensure that every assembly worker accurately executes standards, collectively guaranteeing reliable product delivery.

Every custom-made cable and power adapter leaving our factory undergoes rigorous quality control and testing processes. Leveraging our global production bases, we reliably deliver hundreds of thousands of products to the international market every month, consistently maintaining high quality and consistency.As a leading expert in customized manufacturing, we continuously keep abreast of the latest technologies and industry certifications, constantly enriching our product knowledge base and process solutions. Through close collaboration between engineers and management, we continuously optimize our manufacturing processes; simultaneously, by providing systematic training to our production team and establishing an efficient environment, we ensure that every assembly worker accurately executes standards, collectively guaranteeing reliable product delivery.

Engineering

We are happy to share our experience and our own engineering resources to help our clients find the best solutions for any technical design. This includes electrical engineering, as well as the selection of connectors and wires, and assembly details. Through close collaboration with our clients, we are able to produce high-quality cable prototypes and successfully submit them for client approval.

High level of service

Our experienced quality management team oversees raw materials, production processes, and final products. Our raw material suppliers all comply with RoHS, REACH, and other environmental standards. All raw materials must be inspected before entering the warehouse. During production, each product undergoes an initial inspection daily. Furthermore, the quality team regularly inspects the production line. We have two connection testing processes, one before molding and one after. For the final product, we conduct final testing and provide a delivery report to our customers.

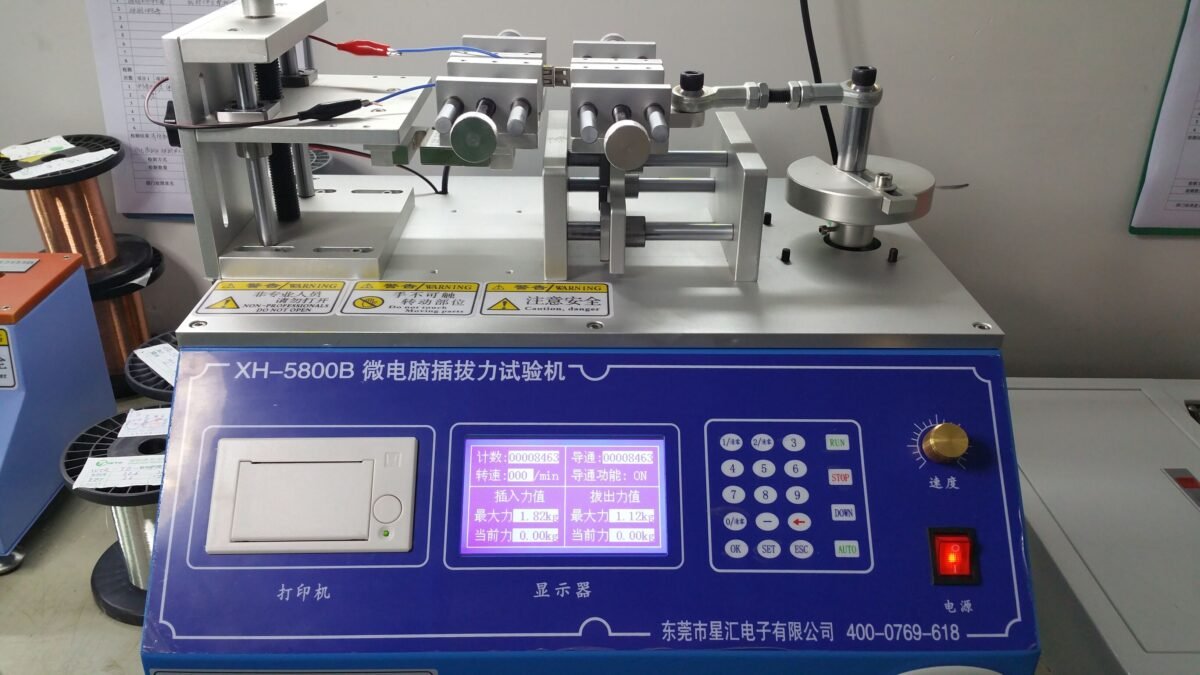

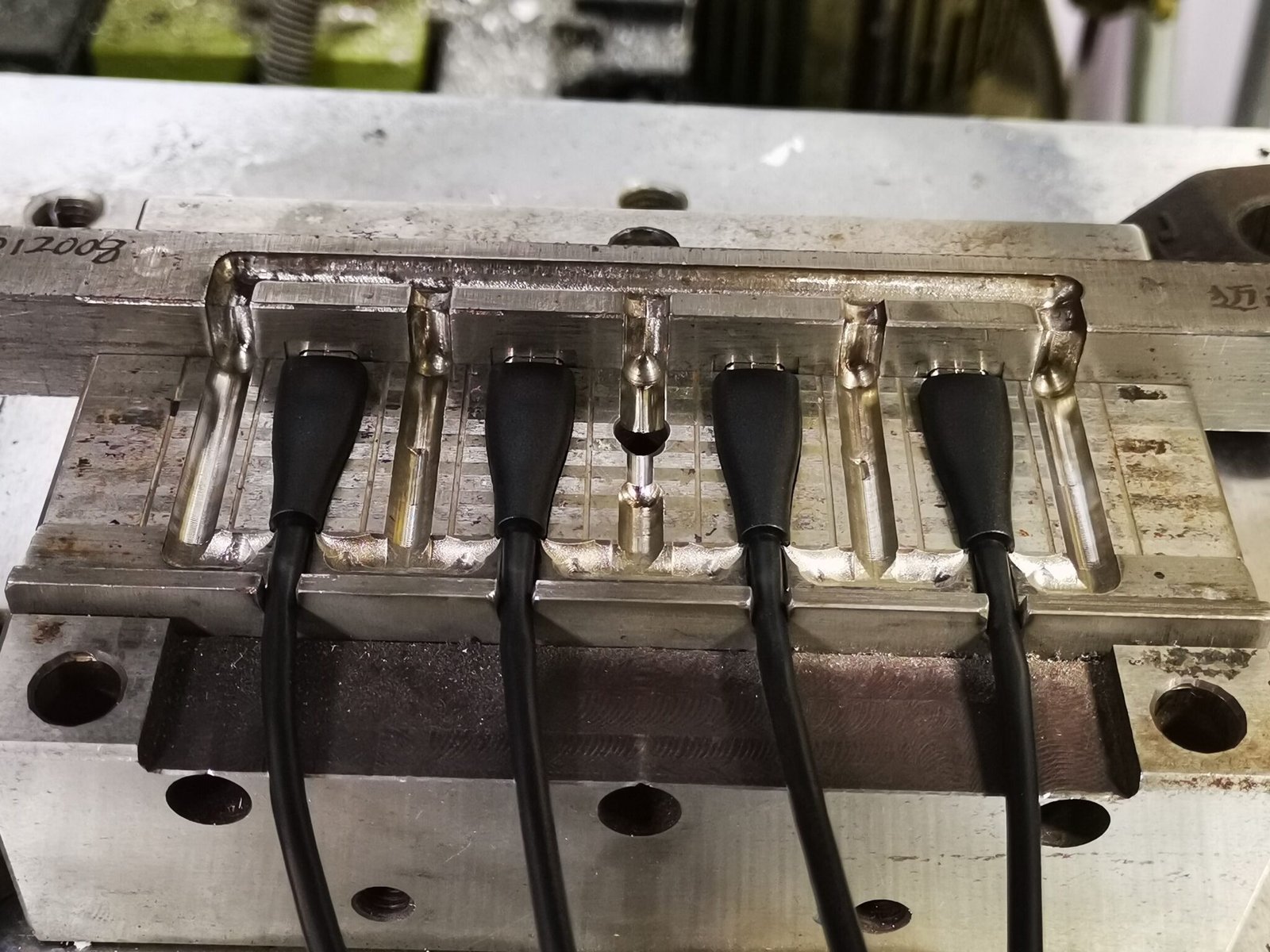

Laboratory quality control

WJW usb cables manufacturers’ quality controlteam has their own laboratory to test our newdesigned usb data cables products. Test eventsinclude Plug and Pull Test, Pull Out Force Test,Swing Test and Salt Spray Test.

We are a professional manufacturer of USB cables and power adapters, supporting OEM and ODM!

We have over 16 years of experience in custom USB cables and power adapters. We have a professional R&D team to meet our clients’ OEM and ODM needs.

Our experienced quality management team oversees materials, production processes, and final products. 100% quality the first time and every single time is our measure of success. On-site defects are unacceptable.

Our advantages

Increase output, productivity, and gain a competitive edge by outsourcing your custom cable assembly manufacturing needs to WJW!

Value

The ability to predict product costs is an absolute necessity for competitiveness in today’s global economy. WJW prioritizes cost reduction and guarantees a fixed unit price to make the predictions a reality.

Speed of launch

Another key asset in today’s market is the ability to deliver products within compressed end-to-end cycle times. Our lean cell environment ensures rapid prototyping and rapid production.

On-time delivery

WJW believes that promises made must be kept. Because on-time delivery is crucial to your success, we strive to continuously improve our performance.

Quality

100% quality the first time and every time is our measure of success. WJW USB cable assemblies are integrated into high-tech products sold worldwide. Field failures are unacceptable.

Our differences

In a high-trading industry, here’s what sets us apart:

Products widely available

When you’re rushing to meet a deadline, nothing’s more frustrating than not being able to get the product you need. We maintain short lead times from manufacturers and high inventory levels for distributors to ensure the right parts are available at the right time and at a reasonable price.

Easier to work with

Yes, quality products and positive communication should be the standard. But we strive to do even better, making your job easier. Our goal is to reduce friction so you can start doing amazing things again. Our team and products are ready to serve you.

Comprehensive partners

For OEMs and distributors, we want to help your projects and businesses succeed. But that’s not the end of the story. Our focus is on improving relationships. You are not part of our deal. We are excited to see you and your community thrive.

Make you an expert

You’ll need to juggle multiple roles, and understanding all the technical aspects required for design can be challenging. Whether it’s datasheets, CAD models, blog content, videos, technical calculators, or a variety of other resources, we can empower you to become an expert in every aspect of your project, helping you achieve greater success in the industry.

Are you looking for a high-quality USB cable and power adapter manufacturer? Need a cost-effective custom solution? Or do you simply want to avoid delivery delays? We can meet all your connectivity and power product needs——from quality and price to on-time delivery.

Our system

Our system safeguards your interests

Quality system

Our quality management system strictly adheres to international certifications including ISO9001 and ISO14001. This commitment to global standards ensures that our entire manufacturing process, from material sourcing to final delivery, is systematically controlled and consistently meets the highest levels of quality and reliability.

Production System

Our factory boasts industry-leading automated production and testing equipment, as well as a production management team, quality management team, equipment management team, and ERP warehouse management team with a strong foundation in systems management theory.

Service System

Our factory offers high-quality products and services at competitive prices, with flexible delivery options and a wide variety of choices. Leveraging cutting-edge industry information and a strong R&D team, combined with cost advantages, a controllable quality management system, flexible delivery services, and a diversified product line, we provide our customers with high-quality R&D results, optimal prices, stable quality control, and timely, convenient, and diverse delivery speeds.

Cost system

Our factory operates on flexible work schedules to better meet our customers’ transportation needs. This advantage allows us to better control product costs, including raw material costs, logistics costs, and manufacturing costs. Through competitive pricing, cost control, and labor efficiency management, we optimize pricing to save our customers reasonable profit margins, thereby enhancing mutual benefit.

Products and Applications

With USB-C becoming the mainstream standard for electronic devices, USB-C cables have become a core product in our manufacturing system. We specialize in producing a wide range of high-quality USB-C cables, covering everything from fast charging cables and data transfer cables to high-end Thunderbolt series cables. For detailed customization support, please feel free to contact us.

Power adapters

Customized adapter solutions with different power ratings, interfaces, and specifications can be provided to meet specific needs.

USB Type-C cables

USB-C to USB-A cables, USB-C to USB-C cables, USB-C to Lightning cables, USB-C to Micro USB cables, USB-C to HDMI cables, USB-C to DisplayPort cables, and more. If you require other types of USB-C cables, they can also be custom-made from our USB-C cable factory.

Applications

Smartphones, smart home devices, computers, industrial equipment, medical devices, etc.

Efficient logistics

Provide on-time delivery logistics

The result? On-time delivery!

On-time delivery is crucial throughout the entire supply chain management process and is key to our business success. Our warehousing department ensures that your products are in sufficient stock before shipment. We ship directly from distribution centers and company stores, including power adapters, chargers, cables, and bulk cables, minimizing supply chain bottlenecks between us and our customers, making us experts in on-time delivery.

Shipping service you know and trust

We offer various shipping methods, including express delivery, air freight, and sea freight. You can select your preferred method on the product page when placing your order, or directly use our recommended solution based on your destination and delivery time requirements.

Express Service

We recommend Express Delivery if time is important and you need to send your electronics economically. With our Express Service, we make sure your shipment is delivered the next working day.

Air Freight

In case of urgent items, air freight shipment is used for global shipments: FEDEX, DHL, UPS, and TNT. Thanks to our large network with the most advanced airlines, we can ship your parcels at lightning speed.

Ocean Transport

Transport by water is cheaper than transport by air and road. We suggest cheap water transport by canal, navigation, or shipping to reduce the cost fee, ensuring your products arrive on time.